Call today for product inquiry: +91- 9810069902.

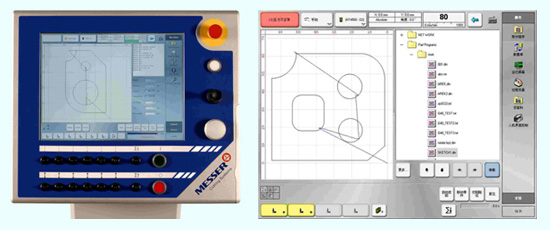

GLOBAL CONTROL P

The newest Control System invented by Messer is the "Global Control". It enables you to enter a new dimension in plate processing and by using unique features, it can help you reduce the downtime and increase your output.

Running on the Microsoft.net architecture makes it possible to connect the machine to your company-wide intranet. Remote access of machine information and easy data capture are new features of Global Control.

Virtual Service is a new and unique feature. It allows our team of experts to remotely diagnose many problems that, in the past, would have required a technician on-site. Through the use of your internet connection, it is possible to build a safe, Virtual Private Network (VPN) connection between your Global Control System and our diagnosis server. After establishing the connection, we are able to view the same data being displayed to the operator back at our facility. Now through the vast amount of diagnostic information in the Global Control, including an on-board oscilloscope, we can perform remote troubleshooting and updates to your software as necessary. Through this feature we can often solve occasional problems within a few hours. Instead of having expensive downtimes, you can now restart your production nearly without delay.

General Information Global Control:

The Human Machine Interface (HMI) based on the newest technology from Microsoft: Microsoft.Net. This enables:

Remote access of machine information

HMI adapts the screen automatically to the process status

Automatic guidance by the HMI when preparing the process

Hand wheel support when editing parameters

Virtual Keyboard or optimized keyboard depending on the input data

Graphical editing of NC-Programs possible

Integration of standard software components from Messer possible - Nesting, Macros etc.

Insensitive to interferences

Modern operating system enables easy integration into a network

Modular structure enables easy retrofitting

Messer own Development enables optimized Processes and customized adaptations

Modern design increases the acceptance of the operator

Modern design increases the acceptance of the operator

Fast operation with fewer errors due to input support and additional help in the HMI

Dynamical Override optimizes the result of cutting

Upward compatibility makes the machine open to future software versions

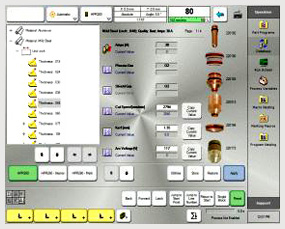

GLOBAL CONTROL S

Intuitve operator interface-e.g. here the process-database with graphic consumable display-saves tedious searching in and for cutting tables

OMNIFLOW

The Omniflow Automatic Gas Control System provides automatic setting and regulation of preheat oxygen, cutting oxygen and fuel gas pressure during oxyfuel cutting. Precise, automatic control of the piercing process is possible for up to five-inch thick mild steel. The Omniflow system is designed for use with MG TurboFlame and ALFA oxyfuel torches. The Omniflow system is integrated into the Global Control Plus, eliminating the need for an extra control. The EdgeMate and EdgeMaster machines powered by the Global Control S require the Omniflow control box.

Optimizes preheat and pierce routines to reduce cycle time and improve cut quality and consistency.

Increases tip life as the slag stream is directed away from the tip.

Pressure sensors on input and output lines provide more effective gas control.

Provides operator with capability to edit cutting parameters for fine-tuning of process.

Built-in diagnostics monitor the cutting process and assist with troubleshooting.

* Note: Each Omniflow Controller delivers enough gas flow to cut up to 4 torch-100 mm. Therefore, two Omniflow controllers provide enough flow for nearly all oxyfuel applications by providing up to 8 torch-100mm of cut.